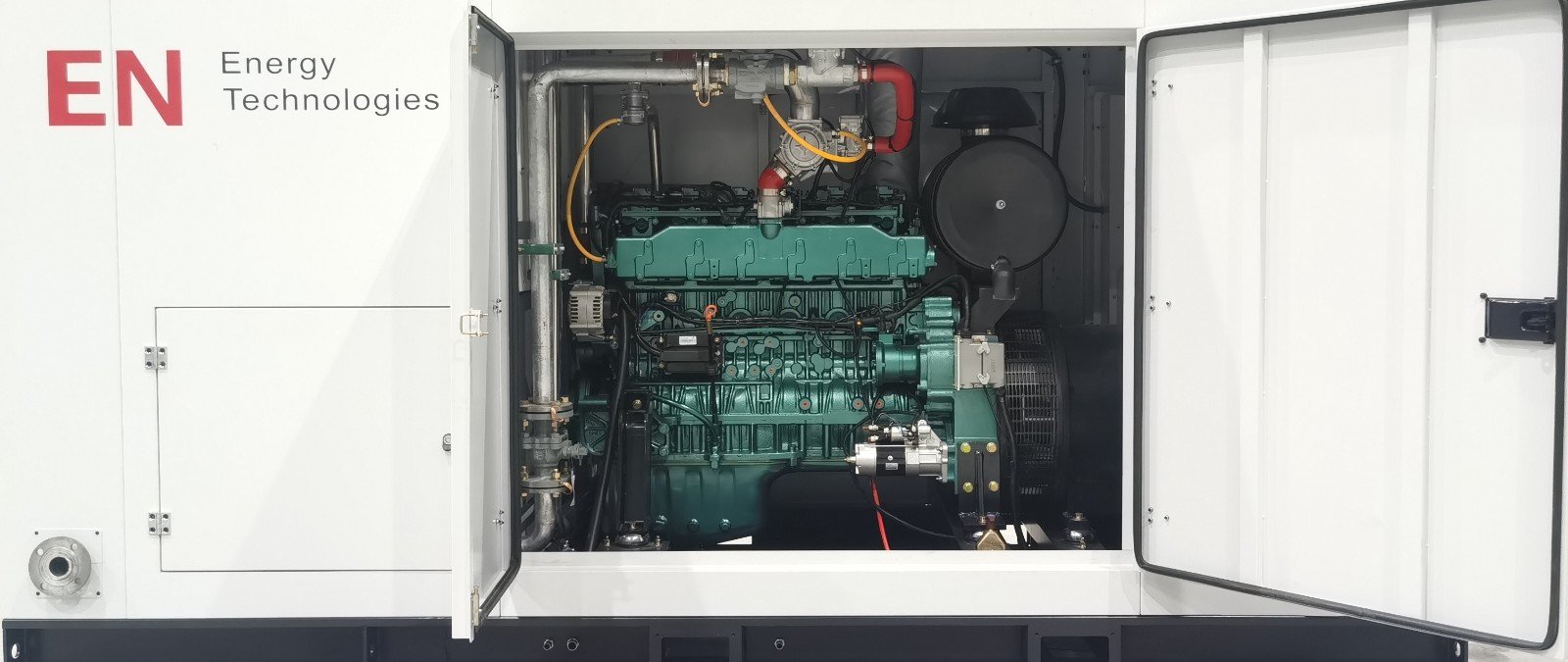

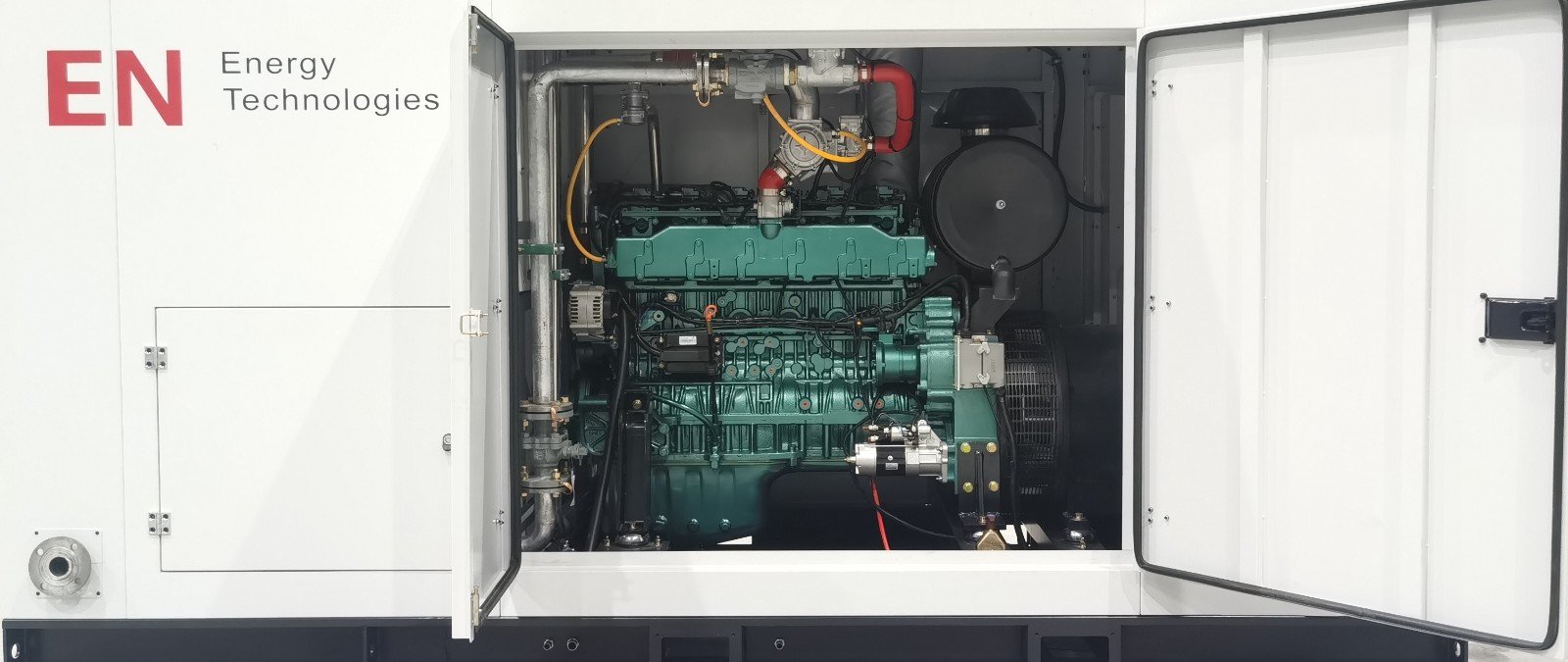

Product Overview: Five parallel-connected 1250kW natural gas power generation core units

In industrial production, emergency power supply for large venues, and regional energy distribution, stable and efficient power assurance is critical. The 1250kW Steyr T12 natural gas generator set (5 units in parallel) showcased on this page is a core solution developed by EN Energy Technology for high-power electricity demands. It integrates CNHTC's Steyr engine—backed by Austrian brand heritage—with EN's deeply customized gas adaptation system, enabling multi-unit coordinated operation to deliver power ranging from 1050kW to 6250kW. - Steyr (CNHTC-Steyr) engine, combined with EN's deeply customized gas adaptation system. This enables coordinated operation of multiple units to meet continuous power demands ranging from 1050kW to 6250kW (5 x 1250kW units in parallel). It finds extensive application in natural gas field associated gas utilization, industrial park self-sufficient power stations, and data center backup power systems, delivering clean, economical, and reliable energy solutions to users.

Core Parameters: Precisely Matching Electricity Usage Scenarios

Basic Performance Parameters

| Parameter | Value | Application Value |

|---|

| Rated Power | 1250kW | Single unit meets the main power supply needs of large equipment |

| Continuous Power | 1050kW | 5 units in parallel provide 5250kW continuous power, suitable for large-load scenarios like industrial parks |

| Rated Capacity | 1562kVA | Ensures stable operation of high power factor loads |

| Frequency | 50Hz/60Hz | Compatible with domestic and international electrical frequency standards |

| Voltage Levels | 0.4kV/0.6kV/10.5kV | Suitable for both low-voltage distribution and high-voltage transmission scenarios |

| Operating Noise | 95dB(A)/7m | Noise reduction of 12-20dB (A) with industrial silencer, compliant with factory noise standards |

| Methane Content Requirement | >85% | Compatible with standard natural gas sources, reducing gas source selection costs |

| Gas Lower Heating Value | Hu ≥ 31.4MJ/Nm³ | Ensures stable output under varying gas source quality |

| Equipment Weight | 24000kg (per unit) | Facilitates room load planning and installation layout |

| Dimensions (L×W×H) | 8300mm×3000mm×3850mm (per unit) | Fits standard industrial plant spaces, reducing modification costs |

Core Parameters of Engines and Generators

| Component | Parameter Details | Advantages |

|---|

| Engine System | Brand: CNHTC (Steyr T12) | Austrian technology heritage, industrial-grade reliability |

| Type: Inline 6-cylinder turbocharged | Improved intake efficiency, reduced fuel consumption |

| Bore × Stroke: 126mm × 115mm | Optimized combustion chamber design, enhanced power output |

| Displacement: 11.6L | Large displacement ensures stable high-power output |

| Compression Ratio: 11 | Adapted for natural gas combustion, reduces carbon buildup |

| Rated Output Power (per cylinder): 280kW @ 1500/1800rpm | Multiple speed options, meets different frequency requirements |

| Lubricating Oil Consumption: <0.3g/kW.h | Low operational cost, extended oil change intervals |

| Ignition Type: Electric controlled individual high-energy ignition | High ignition efficiency, adapts to low gas pressure environments |

| Fuel Control: Stoichiometric combustion + closed-loop control | Precise air-fuel ratio control, reduces gas consumption |

| Generator System | Brand: EN | Deep integration with engine, reduces power loss |

| Model: EN250 1L4 | Designed specifically for high-power gas generator sets |

| Rated Voltage: 400V | Suitable for low-voltage distribution, customizable for high voltage |

| Rated Power (H class): 240kW | High insulation level, strong heat resistance |

| Rated Capacity (H class): 300kVA | Strong overload capability, suitable for impact loads |

| Efficiency: 93.5% (400V operating condition) | High energy conversion efficiency, reduces energy wastage |

| Power Factor: 0.8 | Compatible with common industrial inductive loads |

| Connection Type: D/Y | Flexible switching, meets various distribution needs |

| Excitation Method: Brushless excitation | Easy maintenance, high operational stability |

| Protection Level: IP23 | Dustproof and waterproof, suitable for outdoor semi-open environments |

Product Advantages

(1) High Efficiency & Energy Saving: Low Gas Consumption + High Conversion Efficiency

The generator set features the golden combination of the Steyr T12 engine and EN custom generator, paired with a stoichiometric combustion closed-loop control system. The air-fuel ratio control accuracy can reach ±2%, resulting in a 5%-8% reduction in gas consumption compared to industry-standard products. The generator achieves a high conversion efficiency of 93.5%, further reducing energy transmission losses. For example, in a parallel operation with 5 units, approximately 120,000 Nm³ of natural gas can be saved annually (calculated based on 3000 operating hours per year), significantly lowering energy costs for users.

(2)Stable & Reliable: Industrial-Grade Configuration + Rigorous Testing

Core Imported Components: The engine control system is from ECI (USA), the throttle valve is from Bosch (Germany), spark plugs are from NGK (Japan), and the generator’s main controller can be selected from world-renowned brands like Comap (Czech Republic), DEIF (Denmark), and DSE (UK). This reduces the failure rate of critical components by over 60%.

Full-Process Testing: Each unit undergoes a comprehensive 72-hour full-load continuous operation test, high and low-temperature environmental simulation testing (-20℃ to 50℃), and 12 other rigorous tests, ensuring stable performance immediately after delivery.

Extended Maintenance Cycle: The engine overhaul cycle extends to 36,000 to 60,000 hours, 1.5 times longer than the industry average, reducing downtime for maintenance and improving equipment utilization.

(3) Flexible Adaptability: Multi-Scenario + Customizable Services

Multiple Operation Modes: Supports grid connection, parallel operation, off-grid, automatic control, and other operating modes. In a 5-unit parallel configuration, intelligent load distribution is achieved, automatically adjusting the number of operating units when load fluctuations occur, preventing energy waste from "overpowering" (i.e., underloaded units).

Strong Environmental Adaptability: Equipped with an independent cooling system and temperature control system, the generator can still deliver full power output in high-temperature environments up to 50℃. In temperatures as low as -20℃, the pre-heating system allows for rapid startup.

Customizable Solutions: The generator set can be tailored to meet specific needs, such as adjusting parameters, appearance, structure, and control systems based on user gas quality (e.g., low calorific value natural gas, coal seam gas), voltage levels, room space, and control requirements. For instance, intake systems can be optimized for users in high-altitude areas to ensure no power loss.

Why Choose Multi-Unit Parallel Operation?

(1) Core Value of Parallel Operation

Enhanced Power Supply Reliability: When 5 units operate in parallel, if one unit fails, the remaining 4 units can automatically share the load, preventing an overall power supply interruption. This is particularly crucial for environments with high power continuity demands, such as data centers, hospitals, and semiconductor factories.

Optimized Energy Efficiency: The number of operating units can be adjusted based on power load fluctuations (e.g., only 1 unit starts when load is <1250kW, 2 units start when load is 1250kW-2500kW). Compared to running a single large generator at full load, this approach improves energy utilization by 15%-20%.

Reduced Initial Investment: The number of units can be increased gradually as the power load grows, avoiding a large upfront investment and easing financial pressure on the company.

Ease of Maintenance: Units can be alternated for maintenance without requiring a full shutdown, ensuring continuous production operations.

(2) EN Parallel Technology Advantages

EN has developed a parallel control system specifically for the 1250kW Steyr T12 generator set, utilizing digital synchronization technology. Key features include:

Grid Connection Time: Less than 3 seconds for seamless synchronization.

Load Distribution Accuracy: Within ±2%, ensuring precise load balancing across all units.

Stability for 5+ Units: Enables stable parallel operation for 5 or more units.

Black Start Capability: In the event of a power grid failure, the system can automatically start the units and restore power within 10 seconds, meeting emergency power needs.

Parameters:

AC Alternator data | Gas engine data |

Generator Brand | EN | Engine Brand | CNHTC

|

Motor Model | EN250 1L4 | Engine Model | T12(Steyr) |

Rated Voltage(V) | 400 | Engine type | Inline 6 cylinders-turbocharged |

Rated Power(H class)kW | 240 | Cylinder Bore x Stroke(mm) | 126mm×115mm |

Rated Capacity(H class)kVA | 300 | Displacement (L) | 11.6 |

Motor efficiency (%)/(400V) | 93.5 | Compression ratio | 11 |

Power factor | 0.8 | Rated output power (single) | 280kW-1500rpm/1800rpm |

Connection Methods | D/Y | Maximum lubricant consumption (g/kW.h) | <0.3 |

Rotor insulation class | H class | Minimum air intake (kg/h) | 1190 |

Rated temperature rise | H class | Ignition method | Electronically controlled single-cylinder independent high-energyignition |

Excitation method | Brush-less | Fuel Control Method | Equivalent combustion, closed loop control |

Rotation speed (min- 1) | 1500/1800 | Debugging method | Electronic commissioning |

Shell protection grade | IP23 |

|

|

Application Scenarios

(1) Industrial Park Self-Supplied Power Stations

For high-energy consumption industrial parks such as chemical, metallurgical, and automobile manufacturing, stable power supply is provided using local natural gas resources to replace traditional coal-fired power generation, reducing carbon emissions in alignment with the national "dual carbon" policy. The 5-unit parallel configuration meets peak electricity demands of the park, while during off-peak periods, certain units can be shut down to reduce operational costs.

(2) Associated Gas Utilization in Natural Gas Fields

At natural gas extraction sites, associated gas (with methane content >85%) generated during the extraction process is directly used for power generation. This prevents energy waste and environmental pollution from flaring the associated gas. The generated power can supply the extraction equipment, and surplus electricity can be sold to the grid, improving resource utilization and economic benefits.

(3) Emergency Power Supply for Large Commercial Complexes

Provides emergency power supply for shopping centers, hotels, office buildings, and other commercial venues. The 5-unit parallel configuration can meet the full load requirements for air conditioning, elevators, lighting, etc., ensuring uninterrupted operation during grid power outages. With low noise levels and compact size, the units are well-suited for commercial environments.

(4) Backup Power Supply for Data Centers

Data centers require extremely high power reliability (downtime < 1 minute/year). The 1250kW Steyr T12 generator set (5 units in parallel) can serve as a backup power supply. Paired with an automatic switching system, the generators can start within seconds following a power outage, ensuring continuous operation of critical equipment such as servers and cooling systems.

Remarks

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Altermator: Mecca (Italian brand); Stamford (American brand); Leroy Somer (French brand);

6.Starting mode: electric start;

7.Overhaul period: 36000h~60000h;

8.Generator type: pure copper brushless, automatic voltage regulation;

9.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

Frequently Asked Questions (FAQ)

1. What is the gas consumption rate of the 1250kW Steyr T12 generator set?

A:Under rated power of 1250kW and a gas lower heating value of 31.4MJ/Nm³, the generator set's gas consumption rate is approximately 320Nm³/h to 330Nm³/h, which is lower than the industry average for similar products (typically 340Nm³/h to 350Nm³/h).

2. What additional equipment is required for parallel operation of 5 units?

A:In addition to the 5 main 1250kW units, the following equipment is needed for parallel operation:

Parallel control cabinet (including synchronizer, load distributor),

Gas pressure regulating station,

Centralized cooling system,

Exhaust treatment system (optional).

EN provides a complete parallel system solution, so customers do not need to purchase additional equipment.

3. Can the generator set adapt to high-altitude environments (e.g., above 3000m altitude)?

A:Yes, it can. For users at altitudes above 3000m, EN optimizes the intake system of the generator set (e.g., increasing turbocharger pressure) to ensure that engine power does not degrade (power retention ≥95%). The electrical system is also treated for corrosion resistance to withstand harsh high-altitude environments.

4. Does the generator set meet environmental protection standards?

A:The generator set's emissions comply with the GB 17691-2018 standard for "Vehicle Compression-Ignition and Gas-Fueled Spark-Ignition Engines and Vehicle Exhaust Pollutant Emission Limits and Measurement Methods (China Stage VI)." The NOx emissions are less than 50mg/kWh, meeting environmental protection requirements across various regions in China.