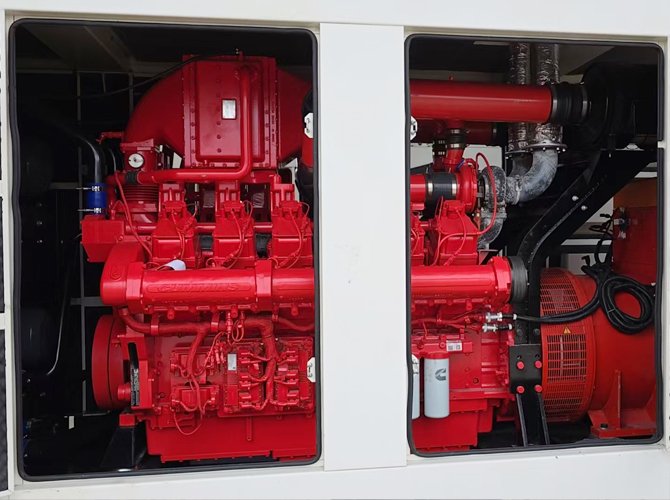

The 1200KW Cummins Biogas Generator Power Plant offers a high-performance, sustainable solution for large-scale power generation from renewable biogas. With a robust Cummins engine and advanced technology, this generator is designed for industrial facilities, agricultural operations, and waste-to-energy projects. It provides a dual benefit: clean, reliable power and reduced environmental impact. By utilizing biogas as a fuel source, this plant supports green energy initiatives, reduces greenhouse gas emissions, and offers significant cost savings.

Rated power:1200kw;

Rated current:1500kVA;

Continuous power:1200kW;

Frequency: 50Hz/60Hz;

Voltage: 0.4kV/0.6kV/10.5kV;

Operating noise:95dB(A)/7m;

Methane content:>50%;

Low heat value:Hu ≥ 16MJ/Nm;

Reference Weight: 12000kg;

Dimensions (L×W×H): 5700mm×1750mm×2400mm;