Key Features of the 1000 kW Cummins Natural Gas Cogeneration Container Genset

Rated Output: Approx. 1000 kW (1 MW) power output in the natural gas version.

Fuel Type – Natural Gas: Designed for pipeline natural gas or other suitable gas fuels, enabling cleaner combustion and lower emissions.

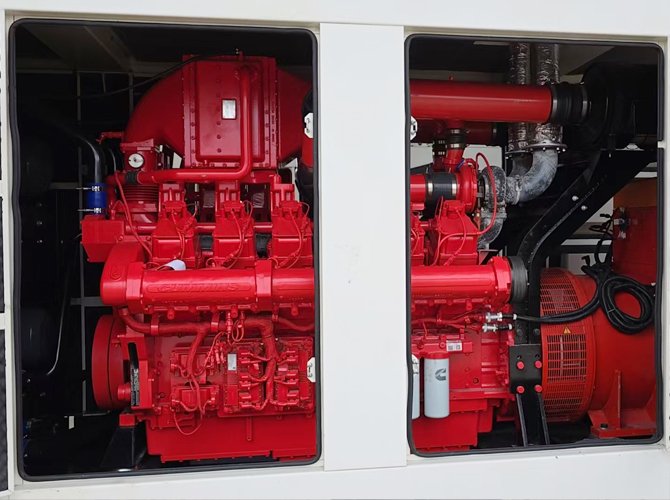

Rainproof Silent Container Enclosure: Weather‑protected containerised design with sound‑attenuation, enabling deployment in outdoor or semi‑exposed locations with minimal noise impact.

Cogeneration (CHP) Capable: Offers ability to recover waste heat (exhaust, jacket water, etc.) for heating or process use, improving overall system efficiency and reducing total cost of ownership.

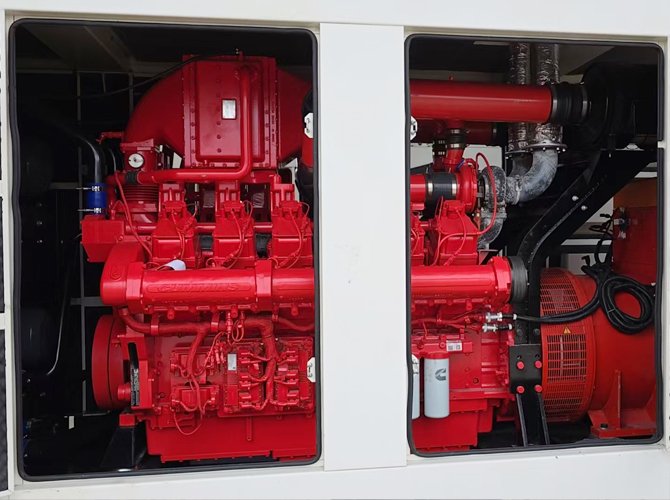

Industrial‑Grade Engine & Alternator: Using Cummins heavy‑duty gas engine platform (e.g., QSK60G for 1000 kW series) and robust alternator design, ensuring durability, high motor starting capability and long service life.

Integrated Control & Protection System: Digital control panel (e.g., Cummins PowerCommand® 3.3 or equivalent) with auto start/stop, paralleling capability (if configured), comprehensive alarms, remote monitoring and load management.

Optimised for Quiet & Outdoor Use: Container design plus sound insulation and engineered ventilation makes it suitable for installations close to buildings or in noise‑sensitive areas.

Flexible Voltage / Frequency Options: Can be configured for 50 Hz or 60 Hz operations and customised voltage levels (e.g., 400 V, 480 V, 6.3 kV) depending on regional grid or microgrid requirements.

High Efficiency & Low Operating Cost: Natural gas fuel combined with high‑density gas engine results in lower fuel consumption per kW, reduced maintenance compared to diesel, and better environmental profile.

Modular & Scalable Design: Containerised solution allows simplified logistics, faster installation, and easier future expansion or relocation.

Applications of the 1000 kW Cummins Natural Gas Container Genset

Industrial & Manufacturing Facilities: Provide reliable prime or standby power for large plants, process equipment, compressor stations, and heavy electrical loads.

Commercial / Data Centres: Ensures continuous power supply in critical environments where reliability is essential, with containerised design reducing site build complexity.

Cogeneration / District Heating: With heat‑recovery capability, ideal for combined heat and power (CHP) applications in campuses, hospitals, hotels, or green energy sites.

Utilities & Grid‑Support / Microgrid: Suitable for utility backup, peak shaving, distributed generation or microgrid projects requiring ~1 MW capacity.

Remote / Modular Installations: Container format simplifies transportation and on‑site installation in remote locations, mining sites, oil & gas facilities or temporary power installations.

Low‑Carbon Transition Projects: For businesses moving from diesel to cleaner fuels, a natural‑gas genset offers a stepping stone to greener energy while maintaining reliability.

Product Parameters:

AC Alternator data | Gas engine data |

Generator Brand | Mecca | Engine Brand | Cummins |

Motor Model | ECO43 2L4A | Engine Model | K50N-G10 |

Rated Voltage(V) | 415 | Engine type | V16, Exhaust turbocharger with wa�ter-cooled turbine housing |

Rated Power(H class)kW | 1040 | Cylinder Bore x Stroke(mm) | 159mm×159mm |

Rated Capacity(H class)kVA | 1300 | Displacement (L) | 50 |

Motor efficiency (%)/(400V) | 96.2 | Compression ratio | 11.5 |

Power factor | 0.8 | Rated output power (single) | 1100kW-1500rpm/1800rpm |

Connection Methods | D/Y | Maximum lubricant consumption (g/kW.h) | <0.3 |

Rotor insulation class | H class | Minimum air intake (kg/h) | 3434 |

Rated temperature rise | H class | Ignition method | Electronically controlled single-cylinder independent high-energyignition |

Excitation method | Brush-less | Fuel Control Method | Equivalent combustion, closed loop control |

Rotation speed (min- 1) | 1500/1800 | Debugging method | Electronic commissioning |

Shell protection grade | IP23 |

|

|

Why Choose the Cummins 1000 kW Gas Power Solution?

Global Brand & Service Network: Cummins boasts an extensive global network of dealers, service centers, and spare parts availability, ensuring uninterrupted maintenance and support throughout the equipment's entire life cycle.

Leadership in Natural Gas Technology: We possess mature and leading technology in the natural gas power generation sector, supporting operations characterized by high reliability and low emissions.

Containerized & Enclosed Design: The solution is perfectly suited for projects requiring rapid deployment, outdoor installation, and enhanced security.

Adaptability for Future Energy Trends: Natural gas generators serve as a reliable and essential bridge for transitioning from traditional fuels toward future renewable energy sources.

Economic and Environmental Advantage: Featuring lower fuel consumption, reduced maintenance requirements, and lower noise and emissions, the solution offers a highly competitive operational and maintenance cost profile.

Modular and Combined Capability: The system supports integration with heat recovery systems (CHP) and is capable of parallel operation, making it highly adaptable for a wide variety of application scenarios.

Remarks

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Altermator: Mecca (Italian brand); Stamford (American brand); Leroy Somer (French brand);

6.Starting mode: electric start;

7.Overhaul period: 36000h~60000h;

8.Generator type: pure copper brushless, automatic voltage regulation;

9.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

Ready to integrate a reliable, high‑capacity natural gas generator system?

Contact us today for full specification, customization options, pricing, installation & commissioning support for the 1000 kW Cummins Natural Gas Generator – Rainproof Silent Cogeneration Container Genset. Let our engineering team help you design the right solution tailored to your operational, environmental and budgetary requirements.