Key Features

Four‑unit parallel configuration (each unit ~250 kW): Delivers ~1,000 kW combined output while enabling flexibility in load sharing, redundancy (one or more units can drop out without system failure), and phased commissioning.

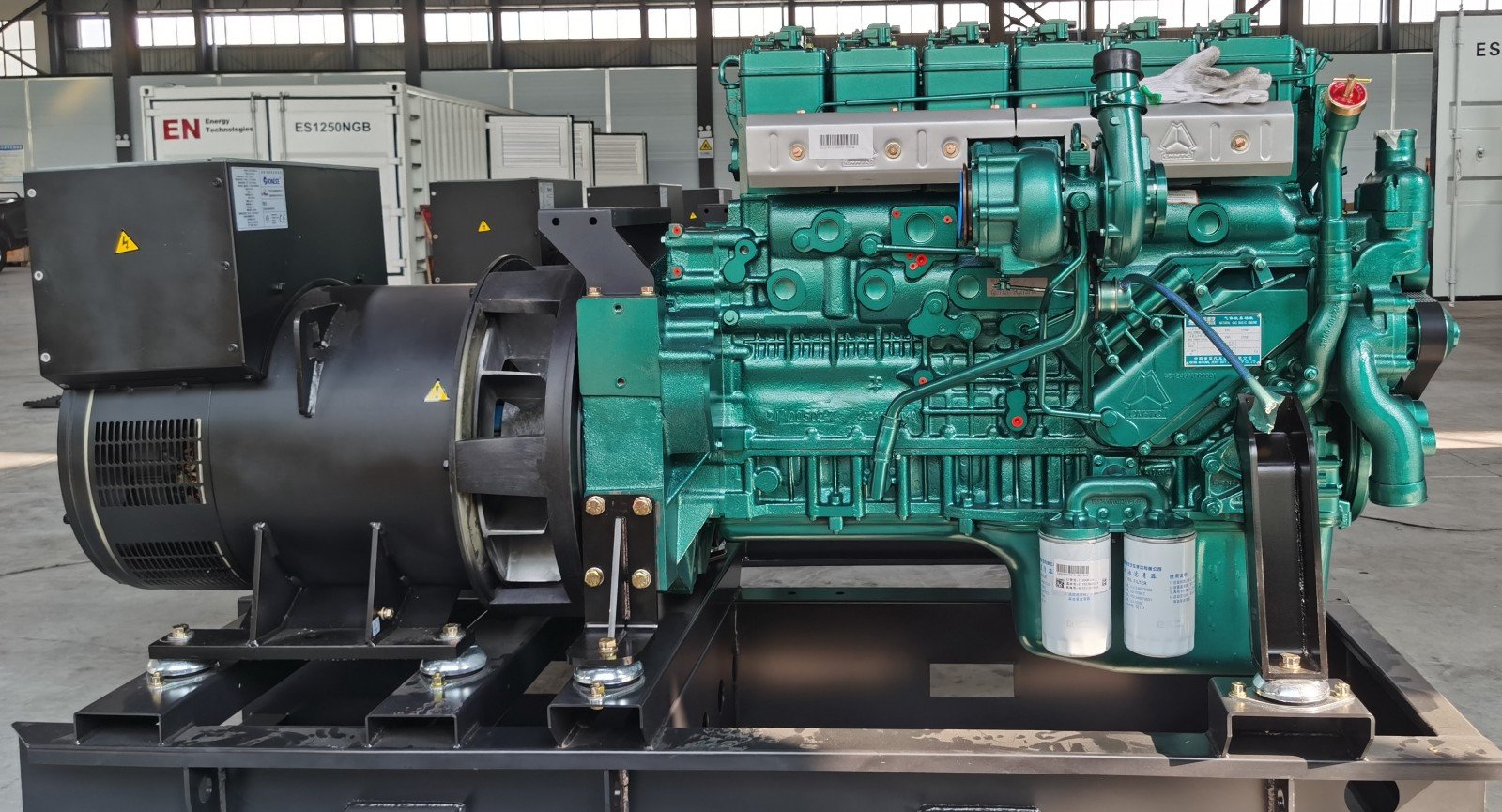

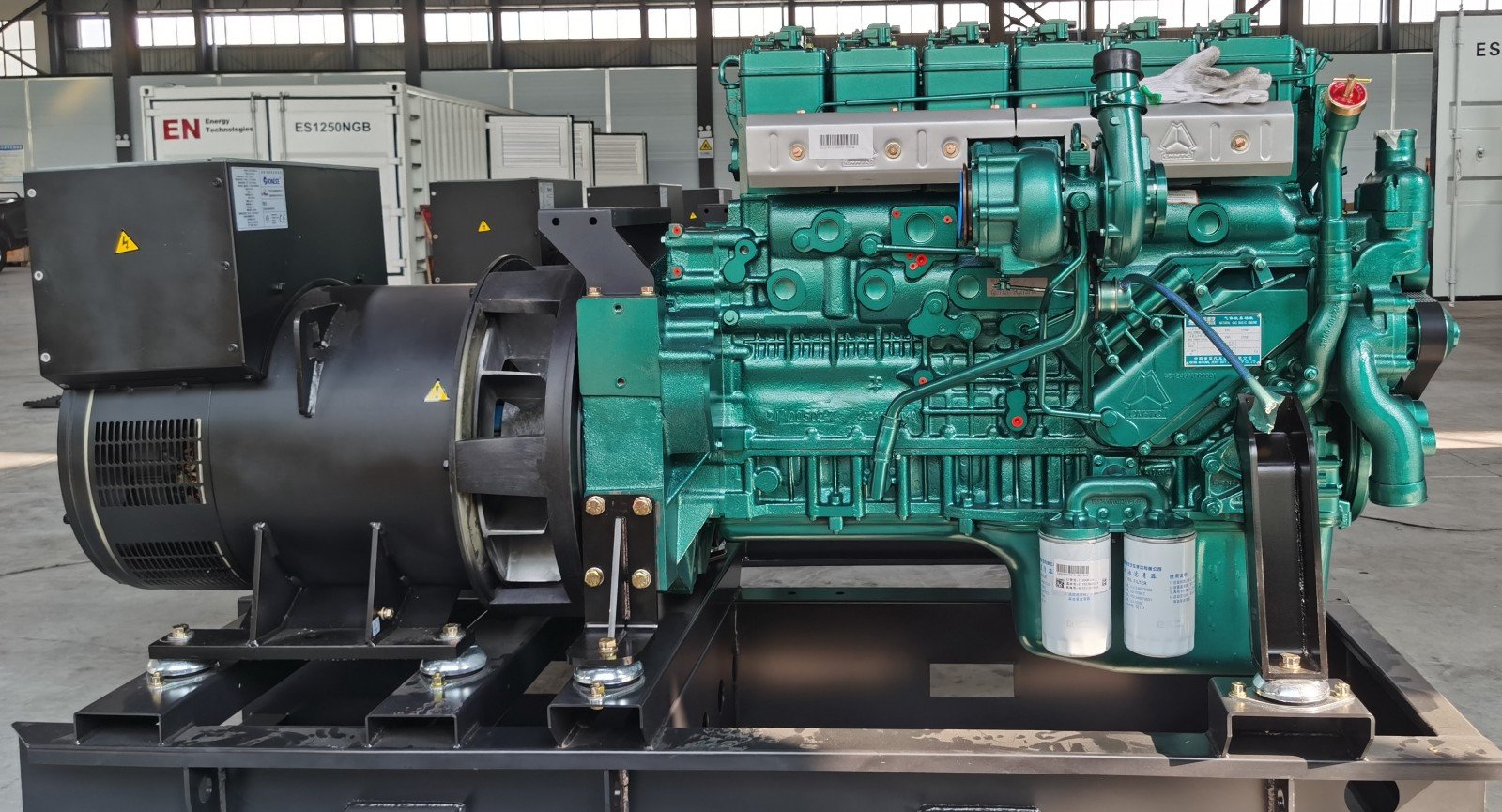

Steyr T12 engine platform: Built for natural‑gas or associated gas operation with features such as lean‑burn combustion, turbocharging and intercooling, high durability in demanding environments.

Containerised 40‑foot module(s): For quick on‑site installation, reduced build‑time, transport ease and streamlined enclosure logistics—especially useful when multiple units need parallel synchronisation in a compact footprint.

Natural gas fuel technology: Clean‑fuel operation means lower emissions (NOₓ, CO, particulates) compared to diesel, improved fuel economy and suitability for regulated or remote sites.

Parallel synchronisation & advanced control system: Ensures seamless automatic load sharing, master/slave coordination, automatic hot‑standby switching and protection functions (overspeed, high water temp, low oil pressure).

Scalable & modular future‑proof: The parallel architecture allows for future expansion (add more modules), or degradation‑handling (run fewer units under lighter loads) while maintaining reliability and performance.

Industrial‑grade alternators, skid‑mounted units: Built for heavy‑duty commercial / industrial use with attention to vibration isolation, thermal cooling, service accessibility and remote monitoring readiness.

Applications

Oil & gas field power supply: For drilling rigs, well‑sites, processing plants where natural gas is onsite or available and high uptime is critical.

Mining & large industrial sites: Sites requiring >1 MW power, modular design, and ability to service or maintain individual units while keeping the system running.

Data centres or large commercial facilities: Where redundancy, clean fuel, containerised footprint and modularity are key.

Distributed generation / micro‑grid / cogeneration: Natural‑gas powered sets like this parallel solution suit hybrid energy systems, CHP (combined heat & power) or as bridging technologies for renewables.

Remote / offshore / infrastructure deployments: Containerisation enables transport via road, sea or rail; suitable for remote sites with limited foundations or where site build‑time must be minimised.

Remarks:

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Altermator: Mecca (Italian brand); Stamford (American brand); Leroy Somer (French brand);

6.Starting mode: electric start;

7.Overhaul period: 36000h~60000h;

8.Generator type: pure copper brushless, automatic voltage regulation;

9.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

Parameters:

| Gas Data |

| Fuel |

| Natural gas [1] |

| Gas intake pressure |

| 3.5Kpa~650Kpa (configure according to project requirements) |

| Methane volume content |

| ≥85% |

| Low hear value (LHV) |

| Hu≥31.4MJ/Nm3 |

| Gas consumption per hour | at 50% load | 156 m3 |

| at 75% load | 220 m3 |

| at 100% load | 292 m3 |

| [1] After the Natural gas components need to be provided by users, the relevant data of the technical manual will be revised. Gas hoses are ECER1 10 approved. Components in the gas train meet directive 90/356/EWG. |

Why Choose This Solution?

High availability through redundancy & modularity: With four modules, the system can tolerate individual unit maintenance without total shutdown.

Compact container‑based design: Simplifies logistics and site preparation; ideal for tight schedules or remote locations.

Advanced Steyr T12 gas engine technology: Built for fuel flexibility, reliability, and demanding applications.

Future‑ready design: Easy to expand, integrate into micro‑grid, cogeneration or hybrid systems.

Cleaner, cost‑effective operation: Natural gas fuel and modern gas engine design reduce fuel cost per kW‑h and emissions burden.

Installation, Operation & Maintenance

Site preparation: Ensure flat, stable base or foundation; sufficient clearance for ventilation and exhaust; gas supply line must meet pressure, flow and gas‑quality specs.

Parallel commissioning: Verify synchronisation controls, load‑sharing logic, protection interlocks, auto start/stop sequences; check each module individually and in full‑system parallel.

Maintenance best practice: Regular inspections of gas supply train, filters, lubrication oil, coolant system, alternator bearings, control system, vibration levels and container housing condition.

Service & spares: Stock critical spare parts (fuel valves, ignition modules, sensors), subscription to preventive maintenance program reduces downtime risk and protects ROI.

Safety & compliance: Gas supply must comply with local regulations (e.g., gas purity, pressure limits), container fire/safety features must be in place, noise and emissions must meet site or local standards.

Ready to implement a robust 1 MW natural gas power solution that delivers modularity, reliability and clean‑fuel efficiency?

Contact us today to explore full specifications, pricing options, container customisation (40‑foot modules), parallel synchronisation architecture and project support for the 1,000 kW Steyr T12 Natural Gas Generator – 4 Units in Parallel (40‑ft solution). Our engineering team is ready to tailor the solution to your site conditions and operational requirements.