Key Features of the 300kW Cummins Biogas Generator Power Plant

Power Output: The 300kW output is perfect for businesses with moderate power needs, including medium-sized manufacturing operations, agricultural facilities, and waste-to-energy plants. It ensures reliable, continuous power.

Fuel Type: Designed to run on biogas, the generator converts organic waste into electricity, making it a sustainable, renewable energy solution. It can also operate on natural gas, providing flexibility depending on fuel availability.

Efficient Energy Conversion: With advanced Cummins engine technology, the 300kW generator ensures high efficiency in converting biogas into electricity, lowering fuel consumption and reducing energy costs.

Environmental Impact: By using biogas, the generator helps to reduce CO₂, NOx, and methane emissions, contributing to cleaner air and supporting sustainability efforts.

Compact Design: The 300kW generator is designed with space-saving in mind, making it easy to integrate into existing infrastructures, whether on farms, industrial sites, or waste treatment plants.

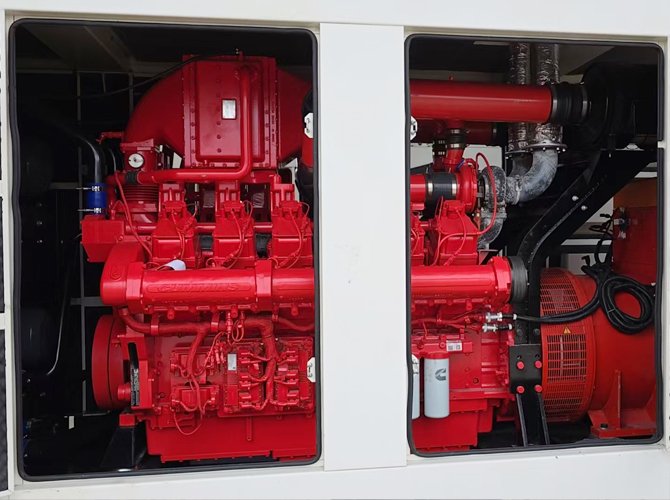

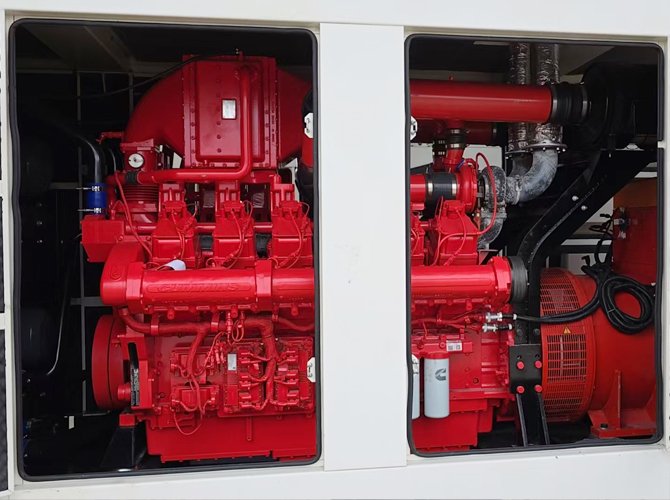

Reliable Performance: Cummins engines are known for their durability and performance. This generator is built to handle long operating hours in demanding environments, ensuring minimal downtime and maximum operational efficiency.

Product Parameters

AC Alternator data | Gas engine data |

Generator Brand | Mecca | Engine Brand | Huachai-Deutz |

Motor Model | ECO40 2L4 | Engine Model | HC12V132 |

Rated Voltage(V) | 415 | Engine type | V-bank-12 cylinders-turbocharged |

Rated Power(H class)kW | 500 | Cylinder Bore x Stroke(mm) | 132mm×145mm |

Rated Capacity(H class)kVA | 625 | Displacement (L) | 23.5 |

Motor efficiency (%)/(400V) | 95 | Compression ratio | 11.5 |

Power factor | 0.8 | Rated output power (single) | 535kW/1500rpm |

Connection Methods | D/Y | Maximum lubricant consumption (g/kW.h) | <0.3 |

Rotor insulation class | H class | Minimum air intake (kg/h) | 2324 |

Rated temperature rise | F class | Ignition method | Electronically controlled single-cylinder independent high-energyignition |

Excitation method | Brush-less | Fuel Control Method | Equivalent combustion, closed loop control |

Rotation speed (min- 1) | 1500 | Debugging method | Electronic commissioning |

Shell protection grade | IP23 | Cooling method | Forced water cooling |

Applications of the 300kW Cummins Biogas Generator Power Plant

The 300kW Cummins Biogas Generator is versatile and can be used in a variety of industries:

Agricultural Operations: The generator is perfect for farms that produce organic waste (e.g., manure, crop residues, or food waste). It allows farms to generate their own power from waste materials, reducing energy costs and improving sustainability.

Industrial Power Supply: Ideal for medium-sized manufacturing plants or food processing facilities that require a stable and cost-effective power supply, the 300kW generator reduces reliance on the grid and provides backup during peak demand.

Waste-to-Energy Projects: Municipalities and waste management companies can use the generator to convert landfill gas or organic waste into electricity, reducing waste and turning it into a valuable energy source.

Remote Power Supply: The generator can be deployed in off-grid or remote locations where power infrastructure is limited or unavailable, providing an independent and sustainable energy source using locally available biogas.

Environmental Benefits of the 300kW Cummins Biogas Generator Power Plant

The 300kW Cummins Biogas Generator helps businesses achieve their sustainability goals by offering significant environmental benefits:

Reduced Greenhouse Gas Emissions: The generator’s use of biogas significantly lowers CO₂ emissions compared to traditional fossil fuels. Biogas also reduces methane emissions, a potent greenhouse gas.

Sustainable Energy Source: Biogas is a renewable energy source, continually replenished through the anaerobic digestion of organic waste. This makes it a long-term solution for clean energy production.

Methane Capture: The generator helps capture methane from organic waste, preventing it from being released into the atmosphere, where it can contribute to climate change.

Waste Reduction: By utilizing organic waste for power generation, businesses can reduce the amount of waste sent to landfills, contributing to a circular economy and reducing environmental impact.

How the 300kW Cummins Biogas Generator Power Plant Works

Biogas Production: Organic waste, such as agricultural residues, food scraps, or landfill gas, undergoes anaerobic digestion to produce biogas—a mixture of methane and carbon dioxide.

Combustion: The methane-rich biogas is burned in the Cummins engine, producing mechanical energy.

Electricity Generation: The mechanical energy is converted into electrical energy, providing a reliable power source for industries, farms, or municipal facilities.

Optional Heat Recovery: The generator can be fitted with a heat recovery system to capture excess heat, which can be used for heating purposes or steam generation, further improving energy efficiency.

FAQ - 300kW Cummins Biogas Generator Power Plant

1. Can the generator run on both biogas and natural gas?

Yes, the 300kW Cummins Biogas Generator can operate on both biogas (methane) and natural gas, providing flexibility based on fuel availability and cost.

2. What are the environmental benefits of using biogas for power generation?

By using biogas, the generator reduces CO₂ and methane emissions, supports renewable energy production, and helps businesses reduce their carbon footprint, contributing to global sustainability efforts.

3. How often does the 300kW Cummins generator require maintenance?

Routine maintenance is recommended every 2000-3000 operating hours, including regular checks, oil changes, and filter replacements to ensure smooth operation.