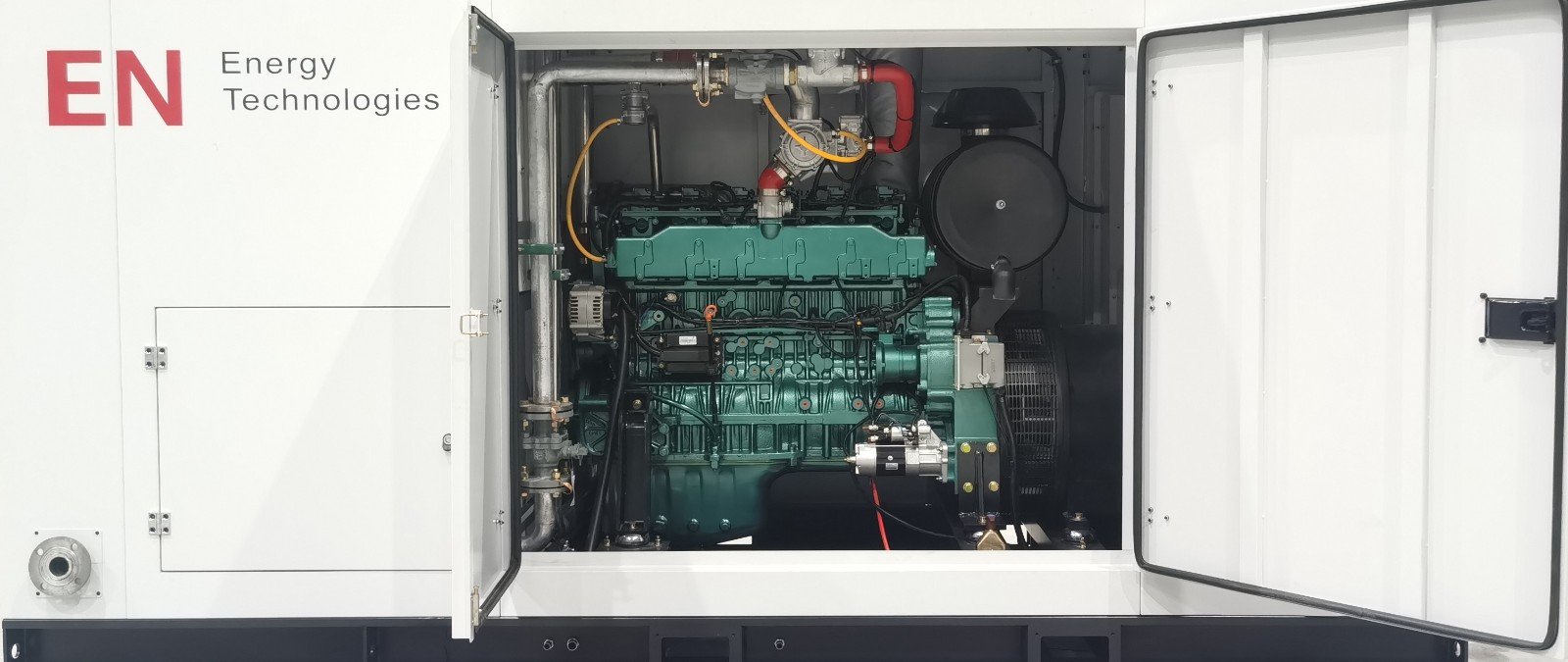

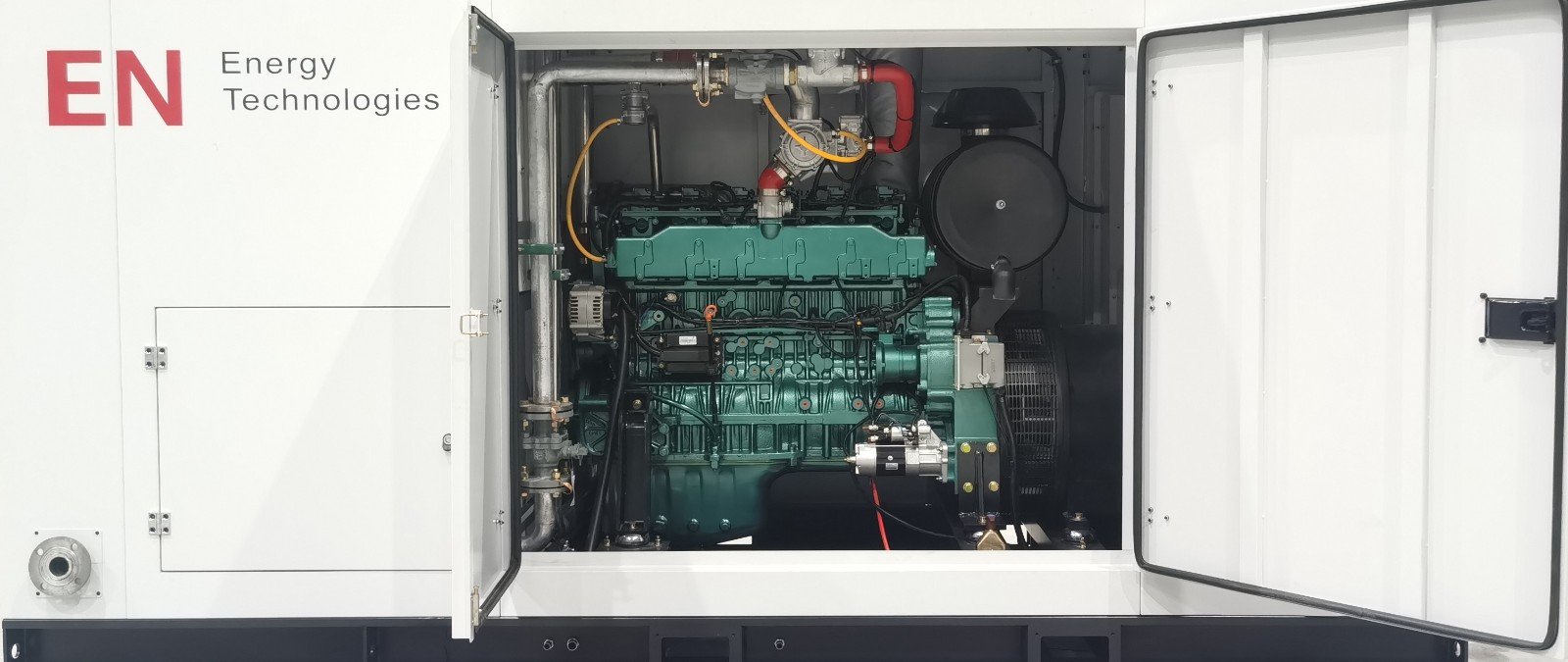

Product Name:250kw Steyr Natural gas generator set power plant

This series of products uses CNHTC-Steyr engines, which is Austrian brand.

All gas engines are designed and developed in conjunction with EN Company according to the use of various combustible gases.

The product power covers 50-1250KW. The product has the advantages of high power per unit, high reliability, low gas consumption, low noise, and strong applicability.

Enhanced Benefits: Steyr T12 Natural Gas Generator Set

| Original Benefit | Refined and Expanded Value Proposition | Technical Rationale & Impact |

| Sustainable Energy Source | Decarbonization and ESG Alignment: Facilitates an immediate and impactful transition to a cleaner, more sustainable energy portfolio. Utilizing natural gas significantly lowers NOx and particulate matter emissions compared to diesel, directly supporting Environmental, Social, and Governance (ESG) initiatives and regulatory compliance. | Cleaner Combustion: Natural gas (CH4) combustion inherently produces lower criteria ai r pollutants, offering a path to reduce a facility's carbon footprint and meet stricter environmental mandates. |

| Reduced Maintenance Costs | Maximized Operational Uptime & OPEX Savings: The engine's advanced design, including high-quality componentry and optimized operation, fundamentally reduces mechanical wear and tear. This translates to significantly extended service intervals and a lower total Operating Expenditure (OPEX) over the generator's entire lifecycle. | Extended Lifespan: Cleaner fuel and advanced technology typically lead to less carbon build-up and cylinder wear, reducing the frequency and cost of major services, such as the cylinder head overhaul (as demonstrated by the competitor analysis). |

| Enhanced Efficiency | Optimized Resource Utilization: Engineered for superior fuel efficiency, ensuring maximum electrical output (kW) from minimum fuel consumption. This optimization not only lowers gas costs but also promotes energy independence and resource conservation. | Improved Thermal Efficiency: The 250 kW unit is designed to operate close to its maximum thermal efficiency, ensuring more of the natural gas energy is converted into usable electricity rather than lost as waste heat. |

| Proven Performance | Reliability in Mission-Critical Scenarios: Backed by a history of proven and reliable performance in the world's most demanding environments. The Steyr T12 engine is a trusted choice for industries worldwide that require uninterrupted, high-quality power, from remote installations to continuous-duty factory operations. | Operational Assurance: Reliability is validated through extensive field use in diverse conditions, confirming its durability for both continuous Prime Power and rapid-response Standby applications. |

Key Features of the 250kW Steyr T12 Generator Set

Power Output: 250kW, providing optimal power for small to medium-sized businesses, industrial operations, and critical backup systems.

Natural Gas Powered: Utilizes clean-burning natural gas as fuel, offering a sustainable energy source with lower emissions compared to diesel generators.

High Reliability: Designed for continuous and standby operation, ensuring reliable power when it’s needed most. Ideal for remote locations, factories, and data centers.

Advanced Technology: The Steyr T12 engine integrates cutting-edge design to maximize fuel efficiency and extend the service life of the generator set.

Cost-Effective: With its exceptional fuel efficiency, the Steyr T12 provides lower operating costs, making it a cost-effective solution for long-term energy needs.

Compact and Space-Saving: The generator set’s design is optimized for easy installation and minimal footprint, making it suitable for installations with limited space.

Eco-Friendly Operation: Designed to meet international environmental standards, the Steyr T12 minimizes emissions and supports businesses in their efforts to reduce their carbon footprint.

Why Choose the 250kW Steyr T12?

Whether you need a backup power solution or a primary energy source, the 250kW Steyr T12 natural gas generator is your go-to choice for high efficiency, sustainability, and cost savings. It is specifically designed to cater to a variety of industries including manufacturing, construction, telecommunications, and more.

1. Superior Economic Performance & Low OPEX

The Steyr T12 is engineered for minimal long-term expense and maximum return on investment.

Exceptional Fuel Efficiency: Its advanced design ensures maximum electrical output (kW) per unit of fuel, leading to lower fuel consumption and significant operational cost savings compared to many conventional generators.

Reduced Maintenance Costs: The engine's low-wear, optimized operation and advanced design lead to extended service intervals and less frequent maintenance, directly contributing to a lower Total Cost of Ownership (TCO) over the generator's entire lifespan.

Reliable Uptime: Designed for both continuous Prime Power and critical Standby operation, its proven reliability minimizes unplanned shutdowns, protecting against lost revenue and production delays.

2. Commitment to Sustainability & ESG Goals

The generator supports corporate environmental responsibility without compromising power output.

Clean-Burning Fuel: By utilizing natural gas, the unit significantly reduces emissions of NOx and particulate matter (PM) compared to diesel.

ESG Alignment: Choosing this generator supports the transition to a greener energy portfolio, helping businesses meet increasingly stringent Environmental, Social, and Governance (ESG) standards and local emission regulations.

3. Compact Design & Operational Flexibility

The physical attributes and operational characteristics ensure easy integration and stable performance.

Optimized Footprint: Its compact, space-saving design simplifies installation in locations with limited physical space, such as urban facilities or cramped industrial sites.

Reliability in Critical Scenarios: With its history of proven performance in demanding environments, the Steyr T12 is a trusted choice for mission-critical applications like data centers, remote factories, and hospitals that require uninterrupted, high-quality power.

The Steyr T12 offers a compelling blend of sustainability, cost control, and reliability, making it a strategically sound investment for your long-term energy needs.

Key Applications

Backup power for essential systems

Remote locations without easy access to the grid

Commercial buildings and data centers

Industrial facilities and manufacturing plants

Remarks:

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Altermator: Mecca (Italian brand); Stamford (American brand); Leroy Somer (French brand);

6.Starting mode: electric start;

7.Overhaul period: 36000h~60000h;

8.Generator type: pure copper brushless, automatic voltage regulation;

9.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

Parameters:

| Gas Data |

| Fuel |

| Natural gas [1] |

| Gas intake pressure |

| 3.5Kpa~650Kpa (configure according to project requirements) |

| Methane volume content |

| ≥85% |

| Low hear value (LHV) |

| Hu≥31.4MJ/Nm3 |

| Gas consumption per hour | at 50% load | 156 m3 |

| at 75% load | 220 m3 |

| at 100% load | 292 m3 |

| [1] After the Natural gas components need to be provided by users, the relevant data of the technical manual will be revised. Gas hoses are ECER1 10 approved. Components in the gas train meet directive 90/356/EWG. |

Contact us today to learn more!