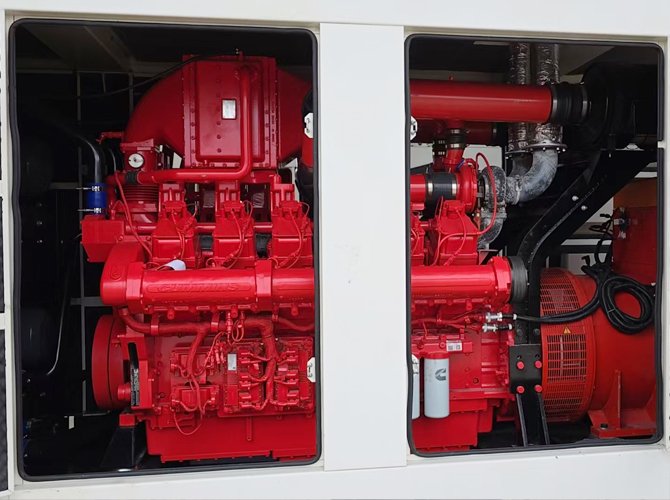

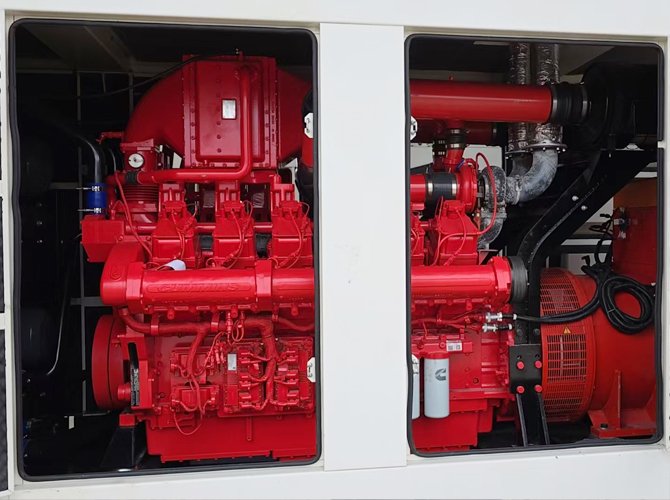

Key Features of the 200 kW Cummins Natural Gas Generator

Rated Output: Approx. 200 kW (or 250 kVA at 0.8 PF), suitable for open‑type power plant configurations.

Fuel Type – Natural Gas: Offers cleaner fuel option compared to diesel, lower particulate emissions, potentially lower fuel cost.

Open‑Type Skid Design: Easier maintenance access, lower enclosure cost, suitable for engine rooms, industrial plants, or outdoor weather‐protected installations.

Engine Model / Technology: Based on Cummins gas‑generator platforms(e.g., QSJ8.9G)which respond quickly to load changes and meet performance demands.

High Efficiency & Reliability: Cummins natural gas generator sets are designed for high electrical efficiency, fuel variation tolerance, and robust operation.

Flexible Voltage / Frequency Options: Can be configured for 50 Hz or 60 Hz systems and a variety of voltages depending on region and customer requirements.

Comprehensive Control & Protection: Digital control system(e.g., Cummins PowerCommand®)with automatic start/stop, voltage/frequency regulation, fault alarms, and remote monitoring capability.

Environmental Compliance: Natural gas engine technology helps reduce emissions of NOₓ, CO₂ and particulates, making it suitable for stricter regulated sites.

Adaptable Installation: Open‑type design allows for custom enclosures, sound attenuation, or integration into larger power plants or microgrid systems.

Product Parameters:

AC Alternator data | Gas engine data |

Generator Brand | Stamford | Engine Brand | Cummins |

Motor Model | UCD274K | Engine Model | MNTAA855-N |

Rated Voltage(V) | 400 | Engine type | 6 cylinders inline, Exhaust turbo-charger with water-cooled turbine housing |

Rated Power(H class)kW | 200 | Cylinder Bore x Stroke(mm) | 140mm×152mm |

Rated Capacity(H class)kVA | 250 | Displacement (L) | 14 |

Motor efficiency (%)/(400V) | 93.3 | Compression ratio | 11.5 |

Power factor | 0.8 | Rated output power (single) | 265kW-1500rpm/1800rpm |

Connection Methods | D/Y | Maximum lubricant consumption (g/kW.h) | <0.3 |

Rotor insulation class | H class | Minimum air intake (kg/h) | 1060 |

Rated temperature rise | H class | Ignition method | Electronically controlled single-cylinder independent high-energyignition |

Excitation method | Brush-less | Fuel Control Method | Equivalent combustion, closed loop control |

Rotation speed (min- 1) | 1500/1800 | Debugging method | Electronic governor |

Shell protection grade | IP23 |

|

|

Applications of the 200 kW Cummins Natural Gas Generator

Commercial buildings & data centres: Provides reliable standby or prime power for mid‑sized facilities with stringent uptime requirements.

Industrial / manufacturing plants: Suitable for supporting process loads, motors, compressors in environments where natural gas is available.

Infrastructure & utilities: Useful in water/waste‑water treatment plants, pumping stations, remote sites where compact open skid genset is beneficial.

Green / transitional power solutions: As companies shift toward lower carbon footprints, a natural gas generator offers a cleaner step versus diesel.

Backup power and peak‑shaving: Can be deployed to provide emergency standby power or to support peak load management in power systems.

Why Choose Cummins Gas Generator Sets?

Brand Strength and Reliability: Cummins possesses deep expertise in the field of natural gas engines and generator sets, backed by an extensive global service and support network.

Advanced Technology: Our latest 175 kW / 200 kW gas generating sets feature the QSJ8.9G 6-cylinder spark-ignited engine, engineered for rapid load response capability.

Natural Gas Advantage: Compared to traditional diesel generators, our natural gas units offer significant benefits in terms of fuel cost efficiency, reduced emissions, and overall environmental performance.

Flexible Customization: The open-set design allows for easy integration and flexible installation into the client’s custom facility layout and equipment configuration.

Exceptional Logistical Support: Supported by our global service network and easily accessible spare parts supply, minimizing the risk of operational downtime and ensuring long-term reliability.

Remarks:

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Altermator: Mecca (Italian brand); Stamford (American brand); Leroy Somer (French brand);

6.Starting mode: electric start;

7.Overhaul period: 36000h~60000h;

8.Generator type: pure copper brushless, automatic voltage regulation;

9.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

Installation, Operation, and Maintenance Guidelines (IOM)

Installation Recommendations

Foundation & Location: Ensure the unit is placed on a sturdy, level foundation with adequate ventilation and exhaust space.

Gas Supply: Verify that the gas supply system (including pressure, quality, and temperature)strictly conforms to the engine manufacturer's specifications.

Accessibility: Dedicate sufficient space and access routes for future maintenance and service.

Startup and Commissioning

Initial Testing: For first-time operation, it is highly recommended to perform comprehensive no-load, half-load, and full-load tests.

System Checks: Thoroughly check and record the gas pressure, control system parameters, unit vibration and noise levels, and verify the correct function of all safety and protection devices.

Routine Maintenance

Periodic Inspection: Regularly inspect the gas delivery system, filters, lubricating oil, coolant levels, unit vibration and temperature readings, control panel status, and electrical cable connections.

Consumables: Follow the manufacturer's specified intervals for replacing consumables (e.g., filters, oil, spark plugs).

Spare Parts and Service

Critical Spares: We recommend maintaining an inventory of critical wear parts(e.g., filters, spark plugs, sensors, control modules)on-site.

Service Contract: Secure a long-term service agreement to ensure operational stability and minimized downtime over the unit's lifespan.

Safety and Environmental Compliance

Safety Measures: Ensure all gas piping meets regulatory standards, the exhaust system is safe, and the generator room is equipped with complete explosion-proof and fire-protection measures.

Compliance: Verify that noise control and emission levels fully comply with all applicable local regulations and codes.

Are you ready to integrate a high‑performance natural gas generator into your facility?

Contact us today for a full specification package, quote, installation support, and tailored configuration for the 200 kW Cummins Natural Gas Generator Open‑Type Power Plant. Let our engineering team assist you in selecting the right solution, ensuring seamless installation and optimized operational efficiency.