Product Features

1. High Efficiency and Energy Saving

Heat Recovery System: The RTO device efficiently recovers heat from the exhaust gases, significantly reducing energy consumption and lowering operational costs.

Outstanding Energy Utilization: The intelligent heat recovery design increases the overall energy efficiency of the system.

2. Versatile Applications

Suitable for treating a wide range of industrial emissions, including VOCs (volatile organic compounds), organic solvents, smoke, and other harmful gases.

Customizable processing capacity and configuration based on client needs, making it adaptable to various industrial applications.

3. Environmentally Compliant

Meets both national and international environmental regulations, ensuring companies avoid penalties and comply with emission standards.

Effectively removes harmful components from the exhaust gases, ensuring clean air emissions.

4. Long Lifespan and Low Maintenance Costs

Built with high-temperature and corrosion-resistant materials to ensure a long service life.

Routine maintenance is simple and cost-effective, lowering long-term maintenance expenses for your company.

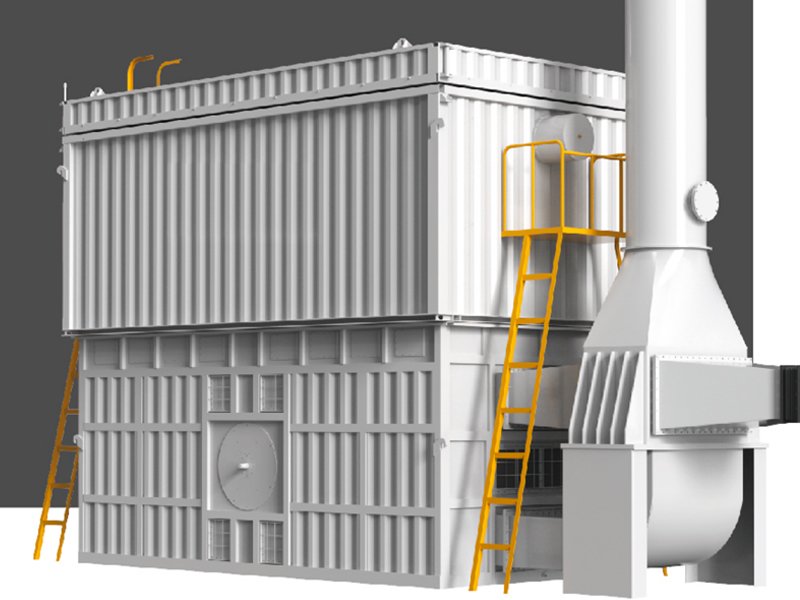

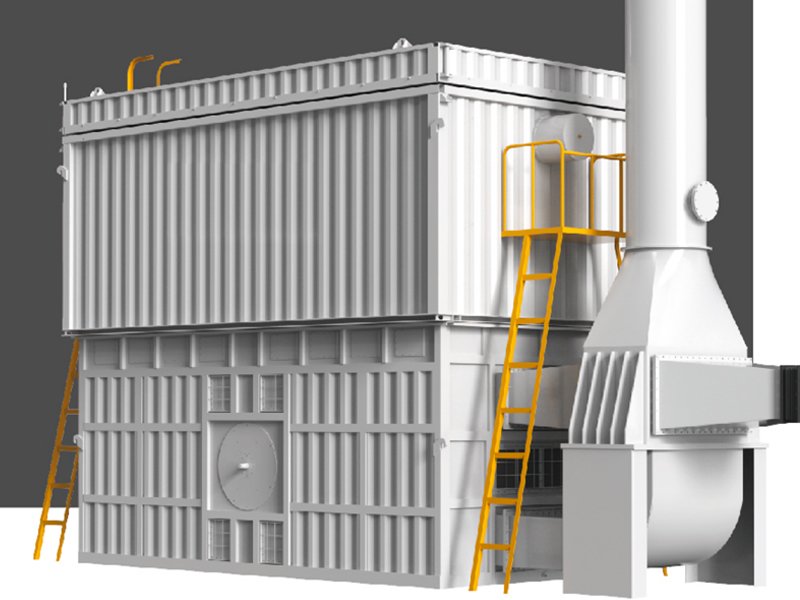

Oxidation system mainly includes coalbed methane gas feed system, main equipment for oxida-tion, hot air utilizing system, etc.

Main equipment for oxidation includes oxidation system, start-up system, control system, moni-toring system and coalbed methane gas mixing system, etc..

Models and specifications: The core model of oxidation system adopting thermalenergy technology is RT40, RT70, RT100 and other oxidation devices, with the treating capacity ofpure methane of 8-20Nm?/min. Multiple devices can be freely combined according to the purecoalbed methane flow on site, and customized design can also be carried out according to theuser's needs.

| Item | RT40 | RT70 | RT100 |

| Handling Capacity of Pure Methane | 8Nm³/min | 14Nm³/min | 20Nm³/min |

| Minimum Inlet Concen-tration (CH₄ vol) | 0.50% | 0.50% | 0.50% |

| Normal Working Concentration (CH₄ vol) | 1%-1.2% | 1%-1.2% | 1%-1.2% |

| Start-up Fuel | Diesel | Diesel | Diesel |

| Start-up Time | ≤5h | ≤5h | ≤5h |

| Heat Supply for Rated Working Condition | ≥2.2million kcal | ≥4.2million kcal | ≥6 million kcal |

| CO Emission | ≤10mg/Nm³ | ≤10mg/Nm³ | ≤10mg/Nm³ |

| NOx Emission | None | None | None |

Applications

Chemical Industry: Efficiently handles waste gases generated during chemical production processes, minimizing environmental pollution.

Coating Industry: Effectively treats organic solvent emissions from painting and coating processes, ensuring compliance with environmental regulations.

Electronics Manufacturing: Removes volatile organic compounds (VOCs) from manufacturing processes, maintaining a clean production environment.

Other Industries: Suitable for various sectors that require exhaust gas treatment, including food processing, automotive manufacturing, and more.

Industry Case Studies

Chemical Industry Case

A leading chemical company installed our RTO device and achieved a significant reduction in harmful emissions. At the same time, the heat recovery system helped the company save energy, meeting regulatory requirements and improving production efficiency.

Frequently Asked Questions (FAQ)

Q: What is the maximum processing capacity of the RTO device?

A: Our RTO units are customizable to handle various capacities. The maximum processing capacity can reach several thousand cubic meters per hour, depending on your needs.

Q: How often does the RTO device need maintenance?

A: The RTO system is designed with high-durability materials, and regular maintenance is straightforward. Typically, a comprehensive inspection and cleaning are required every 6 to 12 months.

Q: How does the device save energy?

A: The core technology of the RTO system recovers the heat from the exhaust gases, reducing the need for additional heating, which significantly lowers energy consumption.

Certifications and Industry Standards

ISO 9001 Quality Management System Certification

Compliant with CE and other international environmental standards

Meets national and regional emission standards, such as EPA, GB, and more