Key Features

Cogeneration Capability (CHP)

The unit not only delivers up to 800 kW of electrical output, but also harnesses engine waste heat (cooling water, exhaust gases) to provide hot water or steam for industrial processes, district heating or HVAC systems.

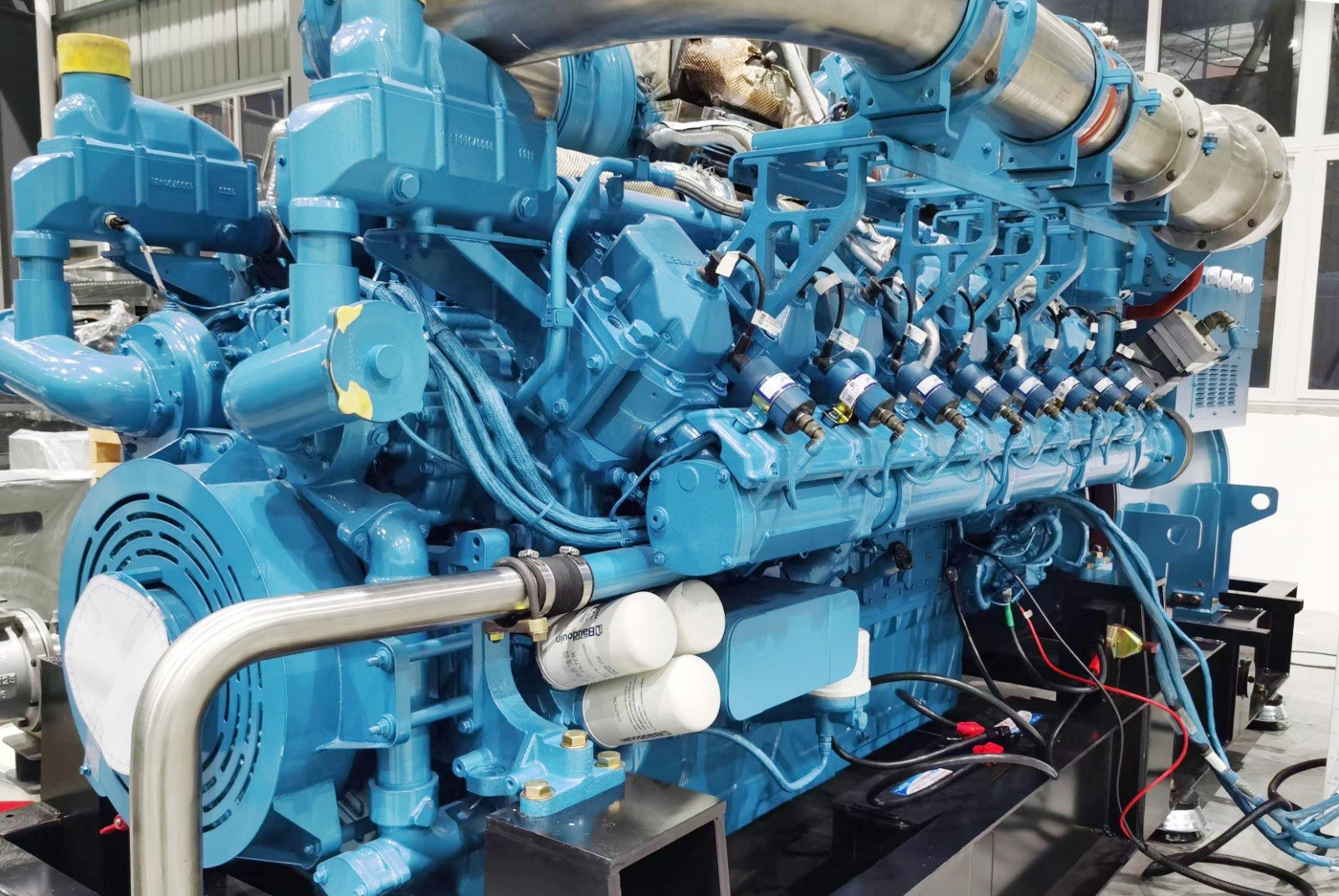

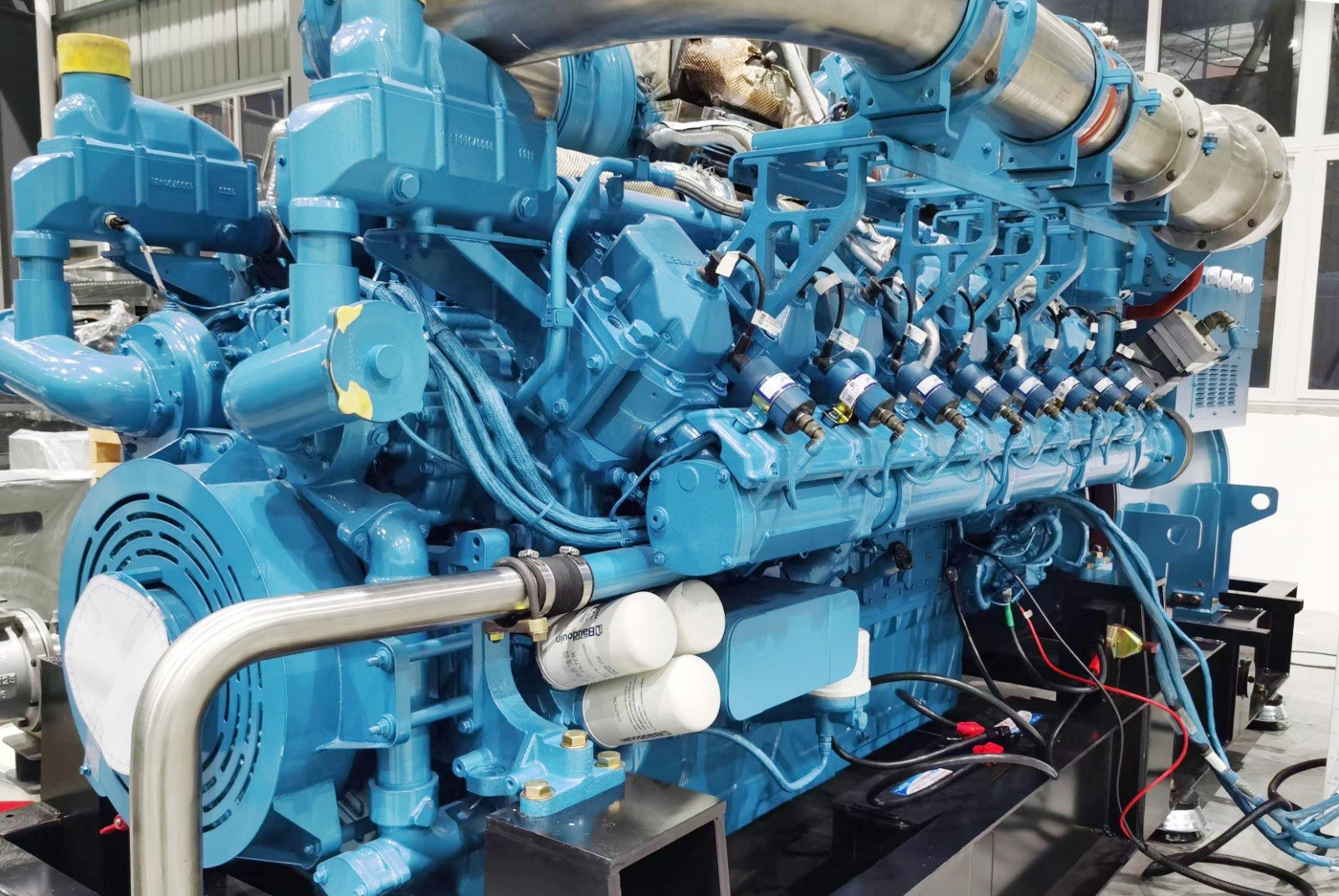

Weichai Gas Engine Technology

Built on Weichai’s advanced gas engine platform, optimised for natural gas, biogas or associated gas. Offers high efficiency, stable performance and long service interval.

Outdoor & Industrial-Grade Protection

Weatherproof enclosure, sound insulation, anti-corrosion coating. Designed for outdoor installations in harsh environments (industrial, remote sites).

Smart Control & Monitoring

Equipped with advanced controller (SmartGen/ComAp) for parallel operation, grid synchronization, remote monitoring, heat-recovery management and fault diagnostics

Product Parameters:

AC Alternator data | Gas engine data |

Generator Brand | Mecca | Engine Brand | Baudouin |

Motor Model | ECO43-2S4A | Engine Model | 12M33D950N |

Rated Voltage(V) | 480 | Engine type | V-type-12 cylinder-turbocharged |

Rated Power(H class)kW | 800 | Cylinder Bore x Stroke(mm) | 150 mm×185 mm |

Rated Capacity(H class)kVA | 100 | Displacement (L) | 39.2 |

Motor efficiency (%)/(400V) | 95.8% | Compression ratio | 12.5 |

Power factor | 0.8 | Rated output power (single) | 950kW/1800rpm |

Connection Methods | D/Y | Maximum lubricant consumption (g/kW.h) | <0.3 |

Rotor insulation class | H class | Minimum air intake (kg/h) | 3890 |

Rated temperature rise | F class | Ignition method | O-Electronically controlled single-cylinder independent high-energy ignition |

Excitation method | Brush-less | Fuel Control Method | Equivalent combustion, closed loop control |

Rotation speed (min- 1) | 1800 | Debugging method | Electronic commissioning |

Shell protection grade | IP23 | Cooling method | Forced water cooling |

Applications

Industrial Parks & Factories :Serves as the primary or backup power source while simultaneously providing thermal energy to production lines or air conditioning systems.

Commercial & Hospitality Buildings:Used to ensure uninterrupted power supply and central heating/hot water systems in buildings.

District Heating & Energy Centres :Utilizing gas resources to provide centralized power and heating for cities or residential communities.

Remote / Off-Grid Sites :The containerized design facilitates transportation and installation, while combined heat and power generation enhances resource utilization efficiency.

Gas Field / Associated Gas Projects:Natural gas or associated gas sources can be used directly, reducing fuel costs.

Remarks:

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Starting mode: electric start;

6.Overhaul period: 30000h;

7.Generator type: pure copper brushless, automatic voltage regulation;

8.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

FAQ

Q1:Is this unit capable of cogeneration?

A1:Yes. The 800 kW unit is specifically designed for CHP application, with a heat-recovery system to use exhaust and cooling water heat for HVAC, hot water or steam.

Q2:Is the containerised unit suitable for outdoor installation?

A2:Absolutely. The containerised design features weatherproof, dust-proof, sound-insulated and anti-corrosion construction, ideal for industrial parks or remote sites.

Q3:Can biogas or associated gas be used on site?

A3:Yes, customization is available. If the gas composition is stable and methane ratio meets requirements, we can provide adapted configuration.

Q4:What advantages does this have compared to traditional diesel gensets?

A4:Key advantages include: cleaner fuel (natural gas), lower carbon emissions, heat recovery capability (CHP), lower operating cost, higher efficiency and modular deployment.