Key Features of the 500 kW Steyr T12 Dual‑Unit Natural Gas Generator

Dual‑unit parallel configuration: Two 500 kW generator sets operating together, enabling flexible load management, redundancy, and ease of maintenance.

Rated output per unit: 500 kW (each unit) at designated frequency/voltage – making a combined capacity up to ~1000 kW when both operate in parallel.

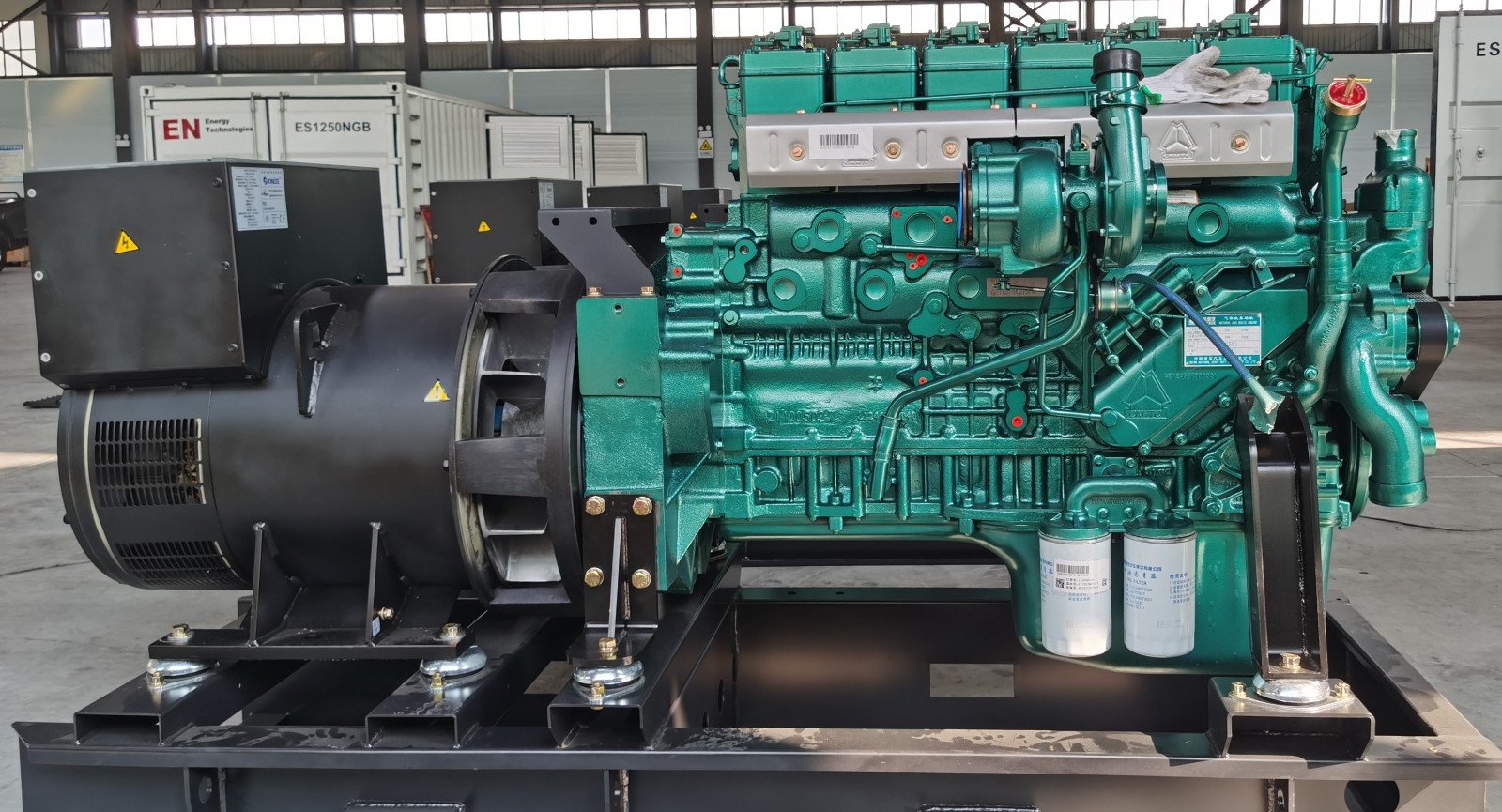

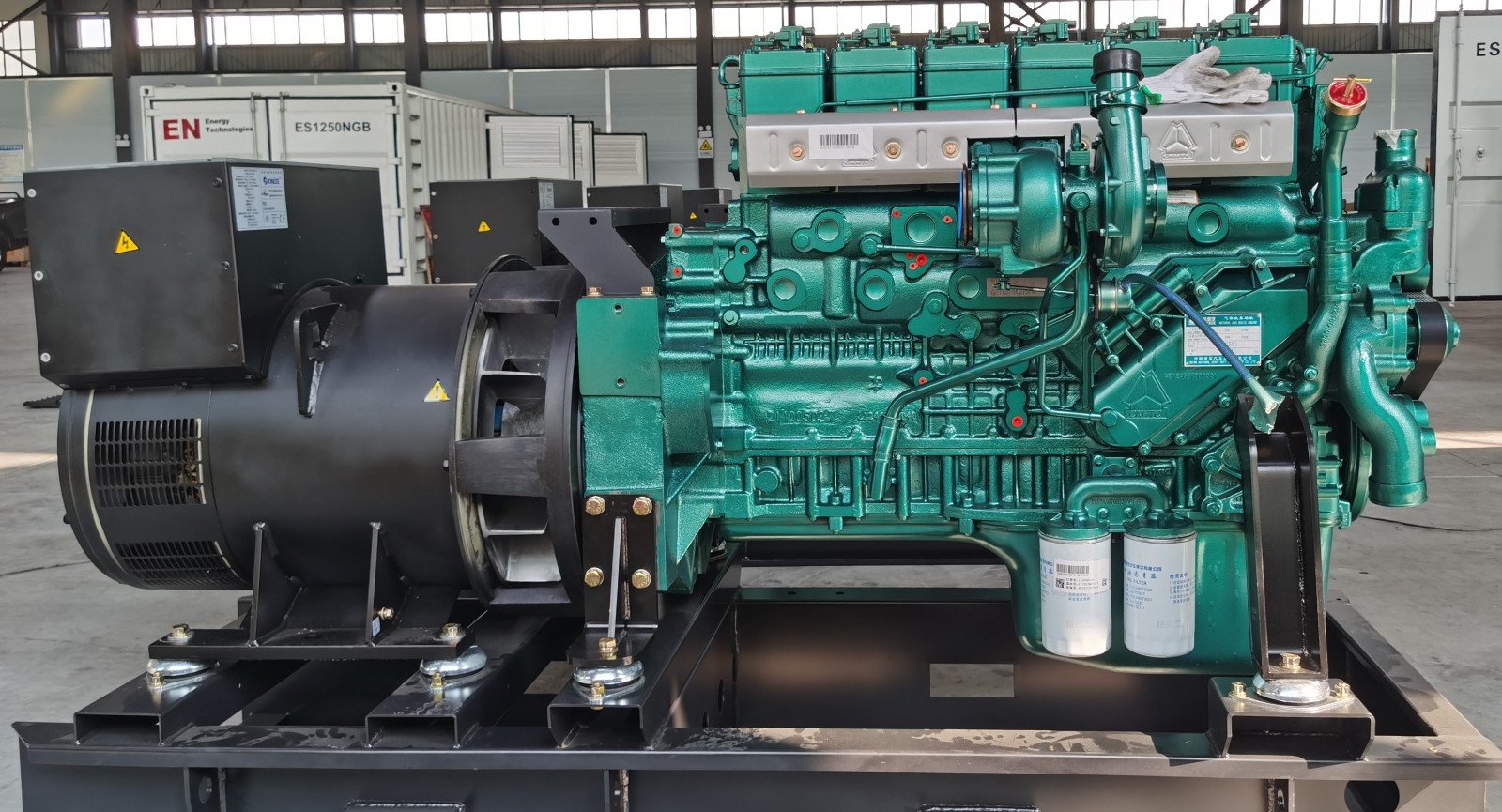

Engine model Steyr T12: Proven gas engine platform with robust design for heavy duty use.

Fuel type: Natural Gas: Cleaner‑burning fuel alternative, suitable for environmentally sensitive applications and regions with gas availability.

Lean‑burn combustion control: The Steyr T12 engine features lean‑combustion and closed‑loop control technology, offering improved fuel economy and lower emissions.

Scalable setup: Parallel configuration allows seamless expansion, load sharing and operational flexibility.

Industrial grade alternator & control panel: Suitable for 50 Hz / 60 Hz operation, various voltages, with automatic load transfer and parallel control systems.

Redundancy & reliability: Even when one unit is offline for service or standby, the second unit continues to supply power—minimizing risk of outage.

Customizable installation: Options for sound‑attenuated enclosures, container‑type modules, high voltage configurations, remote monitoring.

Applications of the 500 kW Steyr T12 Parallel Natural Gas Generator

Industrial manufacturing plants: Reliable backup or primary power for large motors, production lines, critical equipment.

Commercial complexes & data centres: Dual‑unit arrangement ensures high availability and seamless failover for mission‑critical loads.

Oil & gas field/remote deployment: The Steyr T12 platform is referenced in field‑gas applications—suitable for remote sites, exploration camps, modular installations.

Distributed power / micro‑grid systems: With natural gas fuel and parallel units, this system can integrate into micro‑grids or cogeneration solutions.

Green transition projects: As organizations shift to lower‑carbon fuel sources, a natural gas generator set offers a transitional low‑emission solution.

Here is the professional English translation for the Steyr T12 (H2) selling points:

Why Choose the Steyr T12 (H2) Gas Generator Set?

Superior Gas Engine Platform: The Steyr T12 series features a highly mature gas fuel technology platform, making it perfectly adaptable for various gas fuels, including natural gas, associated gas, and other gaseous fuels.

Rapid Load Response: Excellent for applications characterized by sudden load changes, frequent start/stops, or multi-unit parallel operation.

Parallel Operation Advantage: The system design inherently supports multi-unit synchronization (parallel operation), significantly enhancing overall reliability, maintainability, and capacity flexibility.

Exceptional Fuel Economy: Incorporates precise gas injection and closed-loop control technology, which is critical for reducing fuel consumption and minimizing overall operating costs.

Strong Adaptability & Customization: Can be configured according to customer requirements into various versions—such as containerized (container/box-type), silent (soundproof), or high-voltage—to meet diverse national and regional standards.

Remarks:

1.Engine Control System: ECI (American brand);

2.Throttle: Bosch (German brand);

3.Spark plug: NGK(Japanese brand);

4.Generator master controller: Comap (Czech brand); DEIF(Danish brand); DSE(England brnad);

5.Altermator: Mecca (Italian brand); Stamford (American brand); Leroy Somer (French brand);

6.Starting mode: electric start;

7.Overhaul period: 36000h~60000h;

8.Generator type: pure copper brushless, automatic voltage regulation;

9.Operation mode: grid-connected/parallel/isolated/automatic control, etc;

Parameters:

| Gas Data |

| Fuel |

| Natural gas [1] |

| Gas intake pressure |

| 3.5Kpa~650Kpa (configure according to project requirements) |

| Methane volume content |

| ≥85% |

| Low hear value (LHV) |

| Hu≥31.4MJ/Nm3 |

| Gas consumption per hour | at 50% load | 156 m3 |

| at 75% load | 220 m3 |

| at 100% load | 292 m3 |

| [1] After the Natural gas components need to be provided by users, the relevant data of the technical manual will be revised. Gas hoses are ECER1 10 approved. Components in the gas train meet directive 90/356/EWG. |

Ready to elevate your power system?

Get in touch with us today to get complete details for the 500 kW Steyr T12 Natural Gas Generator (2 Units in Parallel) — including custom configuration options, installation & commissioning support, pricing, and service‑agreement plans. Contact our engineering team to design the ideal power plant for your operational needs and environmental goals.